High-Rise Frame Structure

OverviewWZH frame structure system consists of steel columns, steel beams, joint

Overview

WZH frame structure system consists of steel columns, steel beams, joints and supports. The types can be divided into column system, pure frame system and frame support system. Our design team can also design according to customers' requirements.

Column System:

In the column system, vertical steel columns support horizontal beams, forming a grid-like framework to support the building's load. This system is commonly used in buildings where the load-bearing capacity of columns is crucial.

Pure Frame System:

The pure frame system consists of interconnected beams and columns, forming a rigid frame that provides structural stability to the building. This system is ideal for structures requiring resistance to lateral forces such as wind or seismic loads.

Frame Support System:

The frame support system combines the features of both the column system and pure frame system, utilizing additional supports such as braces or trusses to enhance the structural stability and load-bearing capacity of the frame. This system is often employed in buildings with large spans or irregular layouts.

Features of WZH's Fabrication

Typcal Specifications

| Use | Hot Rolled / Built-up H-shapes Steel Columns, Steel Beams, Steel Rafter, Crane Beams, etc. |

| Scope of Work | Fabricate structural steel framing according to the structure drawings. |

| Work Description | Structural steel members complete, with cutting, welding, grit blasting, priming and painting, including all necessary fixing accessories such as stiffeners as specified. |

| Materials | Hot Rolled H Section/ I Section (UB, UC) / Steel Plates |

| Steel Grade | Q355B / Q235C |

| Surface Preparation | By Sand Blasting to SA 2½ DIN EN ISO 12944 T4 standard |

| Priming and Painting | 1 coat of zinc rich primer (60-80 microns) + 1 coat of epoxy-zinc finish paint (60-80 microns), Gray Color. |

| Notes: | All the specifications can be customized. |

| Capacity | 80000 Ton Structural Steel Fabrication Annually, Max thickness 100 mm. |

High-rise frame structures are an essential component of modern architecture, enabling the construction of skyscrapers and other tall buildings that dominate urban skylines around the world. These structures rely on a skeletal frame of vertical steel columns and horizontal beams to support the building's floors, roof, and walls. Here are some key features and concepts related to high-rise frame structures:

Material Efficiency: By using a skeleton structure, high-rise frame buildings efficiently distribute the load to the foundation. Steel, due to its high strength-to-weight ratio, is commonly used, allowing for slender, yet strong, designs.

Wind and Seismic Resistance: Tall buildings are subject to significant wind forces and potential seismic activities. Frame structures are designed with these factors in mind, incorporating features like tuned mass dampers and shear walls to enhance stability and absorb vibrations.

Architectural Flexibility: The use of a frame structure enables greater flexibility in the building’s layout and design. This structural system allows for larger open spaces within the building, as the load-bearing walls are not required for structural support.

Speed of Construction: High-rise frame buildings can be erected relatively quickly thanks to the prefabricated nature of the components. This not only reduces construction time but also labor costs.

Sustainability Considerations: Steel frame structures can be designed with sustainability in mind. Steel is recyclable, and modern construction techniques can minimize waste and energy consumption during the construction process. Additionally, the space efficiency of high-rise buildings can contribute to more sustainable land use in urban areas.

Foundation and Core: The foundation of a high-rise frame structure must be designed to effectively distribute the enormous weight of the building. The core of the building, often housing elevators and stairs, also plays a crucial role in structural integrity, acting as a primary lateral support to resist wind and seismic forces.

Fire Protection: Given the potentially catastrophic consequences of a fire in a high-rise building, steel structures are equipped with fireproofing measures. This can include the application of fire-resistant materials on steel components to prevent structural failure in high temperatures.

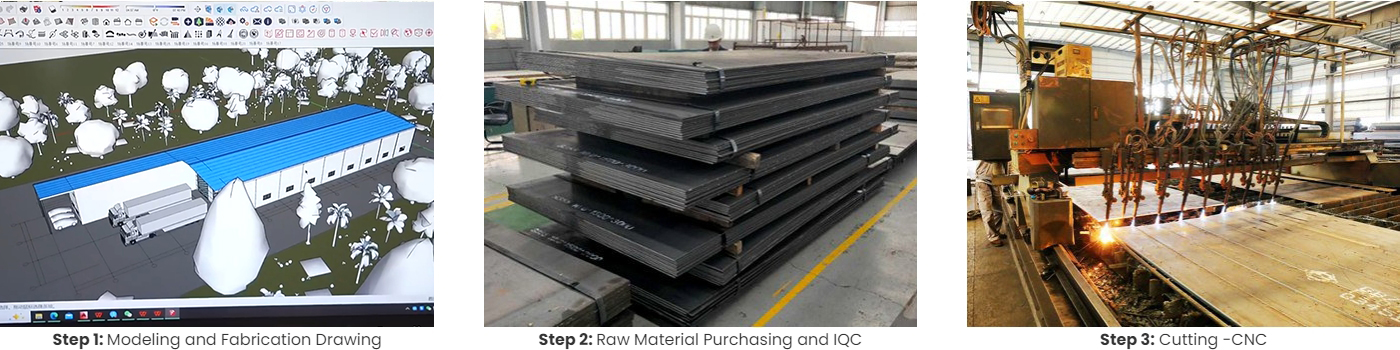

Typcal Fabrication Process of Plate Welded Steel Beams and Columns

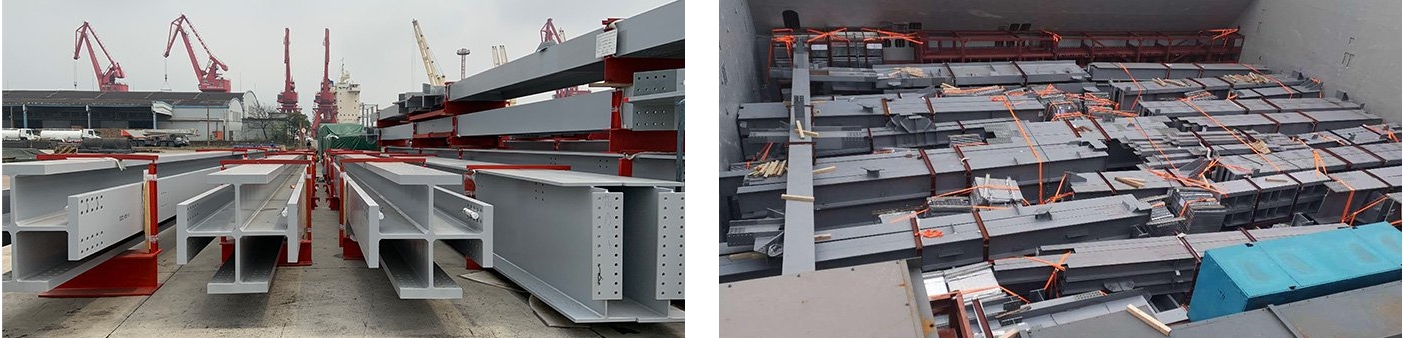

Packing for Container Shipment and Bulk Shipment

FAQ

1.Q: Are your manufacturer or trading company?

A: We are manufacturer, we are group company with over 24 years experiences.

2. How to buy your ideal products?

A: 30% deposit before producing, 70% balance before loading.

3.Q: What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 30 to 40 working days.

4.Q:How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

5.Q:How to install after the goods arriving destination?

A: We will provide detailed shop drawings to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

Write Us

Contact Us for Professional Steel Building Solutions

Inquire About Our Steel Structure Services!