The Significance and Advantages of Steel Fabrication Drawing

The Significance and Advantages of Steel Fabrication Drafting

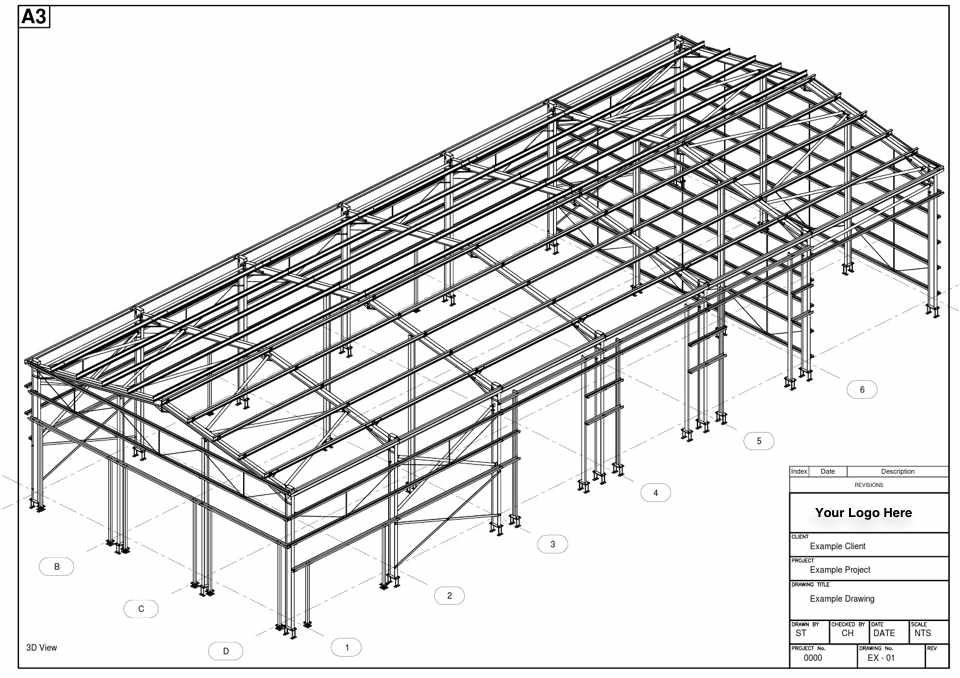

Steel fabrication drafting forms the crucial blueprint guiding the transformation of steel into precision components or frameworks. These technical drawings serve as the foundational script from which metal artisans craft structures, underpinning every cut, join, and weld with empirical accuracy. By meticulously detailing every aspect of the design, these drafts ensure that the envisioned structure can be accurately realized, ensuring that the end product not only aligns with aesthetic intentions but also complies with structural and safety standards.

Benefits of Precision Steel Drafting:

Error Reduction: Drafts serve as a detailed map, reducing the likelihood of costly mistakes and material waste, which in turn ensures an economical production process.

Collaborative Efficiency: Engineers, fabricators, and on-site workers can work concurrently and cohesively, as these drawings provide a unified, clear vision of the project at hand.

Regulatory Compliance: Properly rendered fabrication drawings help in meeting the stringent building codes and regulations that govern construction and manufacturing industries.

Informed Decision-Making: With detailed visualization, stakeholders have the information to make informed decisions, foresee potential issues, and implement preemptive modifications.

In essence, steel fabrication drawings are not merely documents; they are a repository of instruction and insight that drive the entire fabrication process, enabling the creation of high-quality, dependable steel structures with optimal efficiency.