What Is Structural Steel

Understanding Structural Steel: Building the Backbone of Modern Construction

Structural steel stands as the cornerstone of modern construction, a versatile and indispensable material that forms the skeletal framework of buildings, bridges, and a myriad of other structures that shape our urban landscape. With its exceptional strength, durability, and adaptability, structural steel has revolutionized the way we build, enabling engineers and architects to push the boundaries of design and construct structures of unparalleled complexity and scale.

At its core, structural steel is a specialized form of steel alloy engineered to provide superior load-bearing capacity and structural integrity. Composed primarily of iron and carbon, with small amounts of other elements such as manganese, silicon, and copper, structural steel undergoes precise manufacturing processes to achieve the mechanical properties required for construction applications.

The manufacturing process begins with the melting of raw materials in a blast furnace, where iron ore, coal, and limestone are heated to high temperatures to produce molten iron. This molten iron is then refined in a basic oxygen furnace or electric arc furnace to reduce impurities and adjust the chemical composition to meet the desired specifications for structural steel.

Once the desired chemical composition is achieved, the molten steel is poured into molds and solidified into large rectangular blocks known as billets. These billets are then reheated and passed through rolling mills, where they are shaped and formed into the desired structural profiles, such as beams, columns, channels, angles, and plates, through a process known as hot rolling.

Hot rolling involves passing the steel billets through a series of rollers at high temperatures, which deform the steel into the desired shapes while also improving its mechanical properties through grain refinement and alignment. The resulting structural steel profiles exhibit high strength, excellent ductility, and uniformity of composition, making them ideal for structural applications where reliability and performance are paramount.

In addition to hot rolling, structural steel can also be formed through cold rolling or cold forming processes, where the steel is shaped at room temperature to produce precise dimensional tolerances and surface finishes. Cold-formed steel sections, such as channels, angles, and tubes, are commonly used in lightweight construction applications where high strength and versatility are required.

One of the key advantages of structural steel is its exceptional strength-to-weight ratio, which allows engineers to design structures that can support heavy loads while minimizing material usage and construction costs. Compared to traditional construction materials such as concrete or wood, structural steel offers superior strength and durability, enabling the construction of taller, lighter, and more resilient structures that can withstand the forces of nature and the test of time.

Furthermore, structural steel exhibits excellent fire resistance properties, as it does not burn or contribute to the spread of flames in the event of a fire. Instead, structural steel retains its strength and integrity at high temperatures, allowing occupants more time to evacuate and firefighters more time to extinguish the blaze, thus enhancing overall safety in buildings and other structures.

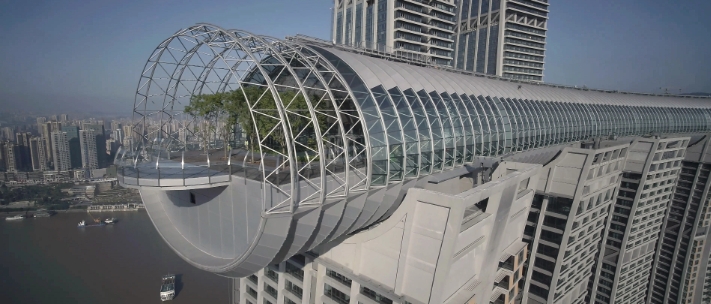

Beyond its inherent physical properties, structural steel also offers unparalleled design flexibility and versatility, allowing architects and engineers to realize their creative vision and push the boundaries of innovation in construction. From iconic skyscrapers and bridges to intricate architectural features and artistic installations, structural steel enables the realization of designs that were once deemed impossible, inspiring awe and admiration in all who behold them.

In conclusion, structural steel stands as a testament to human ingenuity and innovation, a material that has transformed the way we build and live in the modern world. From its humble beginnings as molten iron to its transformation into towering structures that define our urban landscape, structural steel embodies the strength, resilience, and limitless possibilities of human achievement. As we continue to push the boundaries of design and construction, let us remember the integral role that structural steel plays in shaping the world around us and building a brighter future for generations to come.

Unlocking the Potential of Structural Steel: A Comprehensive Guide

Structural steel is a foundational material in modern construction, revered for its exceptional strength, versatility, and durability. This alloy of iron and carbon, often enhanced with additional elements such as manganese and silicon, forms the backbone of buildings, bridges, and other critical infrastructure worldwide. Its utilization has revolutionized the construction industry, enabling engineers and architects to realize ambitious designs and construct structures that defy gravity and stand the test of time.

Composition and Manufacturing Process:

Structural steel is primarily composed of iron and carbon, with trace amounts of other elements added to enhance its mechanical properties. The manufacturing process begins with the extraction of iron ore from the earth, which is then smelted in a blast furnace with coke and limestone to produce molten pig iron. This molten iron is then refined in a basic oxygen furnace or electric arc furnace to reduce impurities and adjust the chemical composition to meet the desired specifications for structural steel.

Once the desired composition is achieved, the molten steel is cast into large rectangular blocks known as billets. These billets are then reheated and passed through rolling mills, where they are shaped and formed into the desired structural profiles through a process called hot rolling. Alternatively, structural steel can be formed through cold rolling or cold forming processes at room temperature to produce precise dimensional tolerances and surface finishes.

Properties and Advantages:

Structural steel exhibits several key properties that make it ideal for construction applications:

High Strength: Structural steel boasts a high strength-to-weight ratio, allowing for the creation of lightweight yet robust structures that can withstand heavy loads and adverse environmental conditions.

Durability: Structural steel is highly durable and resistant to corrosion, making it suitable for use in a wide range of environments, from coastal regions to industrial settings.

Versatility: Structural steel can be easily fabricated into various shapes and sizes to meet the specific design requirements of a project, offering architects and engineers unparalleled design flexibility.

Fire Resistance: Structural steel retains its strength and integrity at high temperatures, making it inherently fire-resistant and enhancing overall safety in buildings and structures.

Applications:

Structural steel finds widespread application in various sectors, including:

Building Construction: Structural steel is commonly used in the construction of skyscrapers, commercial buildings, residential homes, and industrial facilities, providing support for floors, roofs, and other structural elements.

Bridge Construction: Structural steel is a preferred material for bridge construction due to its strength, durability, and ability to span long distances without the need for additional support columns.

Infrastructure Projects: Structural steel is used in the construction of infrastructure projects such as stadiums, airports, railway stations, and power plants, where its strength and versatility are essential for supporting large-scale structures.

Conclusion:

Structural steel stands as a testament to human ingenuity and innovation, playing a vital role in shaping the built environment and driving progress in construction and engineering. As we continue to push the boundaries of design and construction, structural steel will remain a foundational material, enabling the realization of ambitious projects and the creation of a more resilient and sustainable future for generations to come.

Advancements in Structural Steel: Pushing the Boundaries of Construction

Structural steel, the backbone of modern construction, continues to evolve and innovate, pushing the boundaries of what is possible in architectural design and engineering. With advancements in material science, manufacturing techniques, and design methodologies, structural steel has become more versatile, sustainable, and cost-effective than ever before, opening up new possibilities for the construction industry and beyond.

Innovations in Material Science:

Recent advancements in material science have led to the development of high-performance structural steel alloys with enhanced properties, such as increased strength, improved corrosion resistance, and reduced environmental impact. These advanced alloys allow engineers to design lighter, more efficient structures without compromising on performance or durability.

Manufacturing Techniques:

In addition to advancements in material science, manufacturing techniques have also evolved to improve the efficiency and precision of structural steel production. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies allow for the precise shaping and machining of steel components, reducing waste and minimizing production costs. Furthermore, the adoption of automation and robotics in steel fabrication processes has increased productivity and quality control, leading to faster project delivery and improved overall performance.

Sustainability Initiatives:

As sustainability becomes an increasingly important consideration in construction, the steel industry has embraced initiatives to reduce its environmental footprint and promote sustainable practices. This includes the use of recycled steel and scrap metal in production, as well as the implementation of energy-efficient manufacturing processes and waste reduction strategies. Additionally, advancements in steel coatings and surface treatments have improved the durability and longevity of structural steel, further enhancing its sustainability credentials.

Digital Design and Fabrication:

The advent of digital design and fabrication technologies has revolutionized the way structural steel is designed, fabricated, and assembled. Building Information Modeling (BIM) software allows architects and engineers to create detailed 3D models of steel structures, enabling better visualization, coordination, and collaboration throughout the design and construction process. Furthermore, the integration of BIM with computer numerical control (CNC) machining and robotic welding technologies has streamlined steel fabrication and installation, reducing errors and improving efficiency on-site.

Future Trends:

Looking ahead, several key trends are expected to shape the future of structural steel in construction:

Prefabrication and Modular Construction: Prefabrication of steel components off-site and modular construction techniques are expected to become more prevalent, allowing for faster project delivery and reduced construction timeframes.

Integration of Smart Technologies: The integration of sensors, actuators, and Internet of Things (IoT) devices into structural steel components will enable real-time monitoring and maintenance of structures, enhancing safety, reliability, and performance.

Advancements in Sustainability: Continued advancements in sustainable steel production and recycling technologies will further reduce the environmental impact of structural steel and promote its use as a sustainable construction material.

Innovative Applications: Structural steel will continue to be used in innovative ways, such as in the construction of lightweight and flexible structures, adaptive reuse projects, and resilient infrastructure solutions for climate change mitigation and adaptation.

In conclusion, structural steel remains at the forefront of construction innovation, driving progress and shaping the built environment for generations to come. With ongoing advancements in material science, manufacturing techniques, and design methodologies, structural steel will continue to play a pivotal role in the creation of safe, efficient, and sustainable structures that meet the evolving needs of society.

Structural Steel: A Pillar of Modern Infrastructure

Structural steel stands as a bedrock of modern infrastructure, supporting the development of robust, resilient, and visually striking buildings, bridges, and other vital structures. Its enduring presence in construction projects worldwide is a testament to its unmatched strength, versatility, and reliability. As we look to the future, structural steel remains poised to play a pivotal role in shaping the built environment and meeting the evolving needs of society.

Strength and Durability:

One of the defining characteristics of structural steel is its exceptional strength-to-weight ratio, which allows for the construction of tall, spacious structures without sacrificing stability or safety. Its inherent durability makes it well-suited for withstanding the forces of nature, including wind, seismic activity, and environmental degradation, ensuring the longevity and resilience of the built environment.

Versatility and Adaptability:

Structural steel's versatility extends beyond its physical properties to encompass its ability to adapt to diverse design requirements and construction challenges. Whether used in the form of beams, columns, trusses, or frames, structural steel can be tailored to meet the unique demands of each project, enabling architects and engineers to unleash their creativity and bring visionary designs to life.

Efficiency and Sustainability:

In an era marked by a growing emphasis on sustainability and resource efficiency, structural steel shines as a beacon of environmentally responsible construction. Its recyclability, combined with efficient manufacturing processes and innovative design solutions, minimizes waste and energy consumption while maximizing the lifecycle value of structures. Additionally, the use of structural steel often results in shorter construction timelines and reduced site disruption, further enhancing its sustainability credentials.

Innovation and Advancement:

As technology continues to evolve, so too does the field of structural steel construction. Emerging technologies such as Building Information Modeling (BIM), advanced fabrication techniques, and robotic automation are revolutionizing the way structural steel is designed, fabricated, and assembled. These innovations not only improve efficiency and precision but also open up new possibilities for architectural expression and structural performance.

Collaboration and Excellence:

The success of structural steel projects is built on collaboration and expertise, bringing together architects, engineers, fabricators, and contractors to deliver exceptional results. By fostering a culture of collaboration and continuous improvement, the structural steel industry continues to push the boundaries of what is possible, delivering projects that inspire, endure, and enrich the communities they serve.

Conclusion:

In an ever-changing world, structural steel remains a steadfast symbol of progress, innovation, and excellence in construction. From iconic skyscrapers and bridges to industrial facilities and public spaces, its impact on the built environment is undeniable. As we embrace the challenges and opportunities of the future, structural steel will continue to stand tall as a pillar of modern infrastructure, supporting our aspirations and shaping the world we inhabit.

Structural Steel: Building Tomorrow's Landmarks Today

Structural steel stands as the backbone of modern construction, forging the skyline of cities around the globe and anchoring the infrastructure upon which society relies. Its versatility, strength, and sustainability have made it the material of choice for architects and engineers seeking to realize their boldest visions and create structures that captivate the imagination and stand the test of time.

Innovative Design Solutions:

The inherent properties of structural steel, including its high strength-to-weight ratio and malleability, enable architects to push the boundaries of design and create structures that defy convention. From sweeping curves to soaring cantilevers, structural steel provides the flexibility and freedom to bring even the most ambitious architectural concepts to life.

Iconic Landmarks:

From the iconic Eiffel Tower to the sleek Burj Khalifa, structural steel has played a central role in the creation of some of the world's most recognizable landmarks. These towering achievements stand as testaments to the ingenuity and craftsmanship of those who work with steel, inspiring awe and admiration in all who behold them.

Engineering Excellence:

Behind every architectural marvel lies a team of skilled engineers who harness the power of structural steel to realize their vision. Through meticulous planning, analysis, and execution, these professionals ensure that steel structures are not only aesthetically stunning but also safe, efficient, and resilient in the face of environmental challenges and unforeseen circumstances.

Sustainable Solutions:

As concerns about climate change and resource depletion continue to grow, the importance of sustainable construction practices has never been greater. Structural steel, with its high recyclability and minimal environmental impact, offers a sustainable solution for meeting the world's growing infrastructure needs while minimizing carbon emissions and conserving natural resources.

Future Prospects:

Looking ahead, the future of structural steel is bright and full of promise. Advances in technology, such as 3D printing and digital fabrication, are opening up new possibilities for how steel is designed, manufactured, and assembled. These innovations, coupled with a growing emphasis on sustainability and resilience, will continue to shape the evolution of structural steel and its role in construction for generations to come.

Conclusion:

In the ever-changing landscape of construction, one thing remains constant: the enduring strength and versatility of structural steel. As we continue to push the boundaries of what is possible, steel will remain a trusted ally, enabling us to build the landmarks of tomorrow and create a better, more sustainable world for future generations to enjoy.