Comparison between flexible connections and rigid connections

In the realm of structural engineering, the selection of connection systems holds paramount importance as it significantly influences the behavior and performance of a structure. Among the plethora of connection types available, flexible and rigid connections stand out as common choices, each offering distinct advantages and applications. This article delves into a comparative analysis of these two connection types, elucidating their characteristics, applications, and respective benefits.

Comparison between flexible connections and rigid connections

1. A brief introduction to the connection systems in steel structures

Connection systems in steel structures are integral to joining various steel components such as columns, beams, trusses, and bracing together to form a cohesive and functional building or infrastructure. These connection methods are essential elements that contribute significantly to the overall performance and efficiency of the construction process. While there exist several types of connection systems, each with its own characteristics and advantages, they collectively serve the purpose of ensuring structural integrity and stability.

Welded Connections:

- Welding involves fusing steel components together using heat and pressure.

- It offers high strength and rigidity, making it suitable for critical load-bearing connections.

- Welded connections are efficient and often preferred for their simplicity and cost-effectiveness.

Bolted Connections:

- Bolted connections utilize bolts and nuts to secure steel components together.

- They offer ease of assembly and disassembly, facilitating construction and potential future modifications or repairs.

- Bolted connections are suitable for applications requiring flexibility and adaptability.

Riveted Connections:

- Riveting involves driving a metal pin (rivet) through aligned holes in the steel components and then deforming its end to create a secure joint.

Historically widely used, riveted connections offer excellent shear resistance and durability.

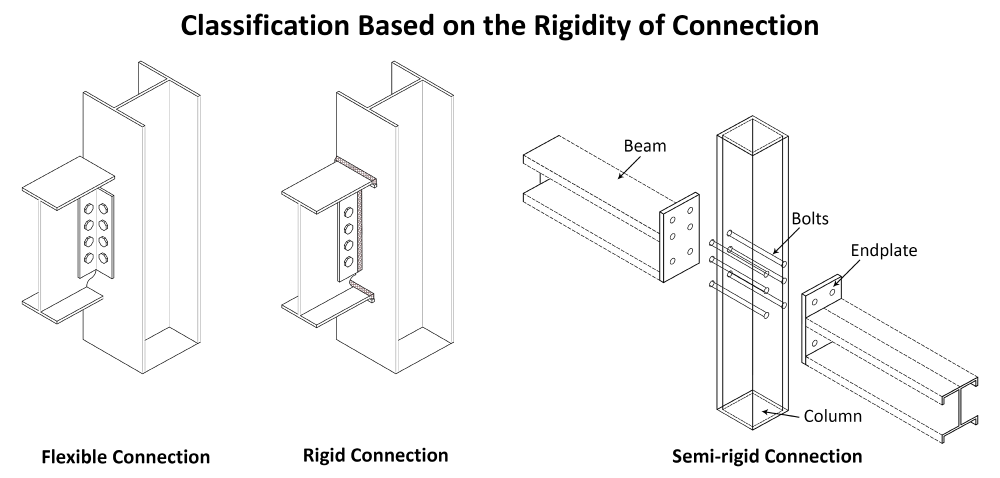

2. Comparison between flexible connections and rigid connections

2.1 Load Transfer

Flexible connections primarily transmit axial and shear forces while allowing for movement.

Rigid connections transfer axial and shear forces, along with bending moments, between connected members. They are more effective in handling heavier loads and resisting bending moments.

2.2 Movement and Flexibility

Flexible connections allow for relative movement and flexibility between connected members, accommodating deformations, thermal expansion, and seismic forces.

Rigid connections restrict movement, providing greater structural stiffness and stability.

2.3 Design and Construction

Flexible connections, like bolted connections, offer easy installation, adjustment, and disassembly if needed.

Rigid connections, especially welded connections, require careful design and skilled construction for proper execution.

Flexible connections are commonly utilized in structures where a certain degree of movement or flexibility is desirable, such as trusses, bracing systems, or structures subjected to dynamic loads. These connections allow for relative motion between connected members while still maintaining structural integrity. They can accommodate thermal expansion, wind-induced vibrations, and other environmental factors without compromising the stability of the overall structure.